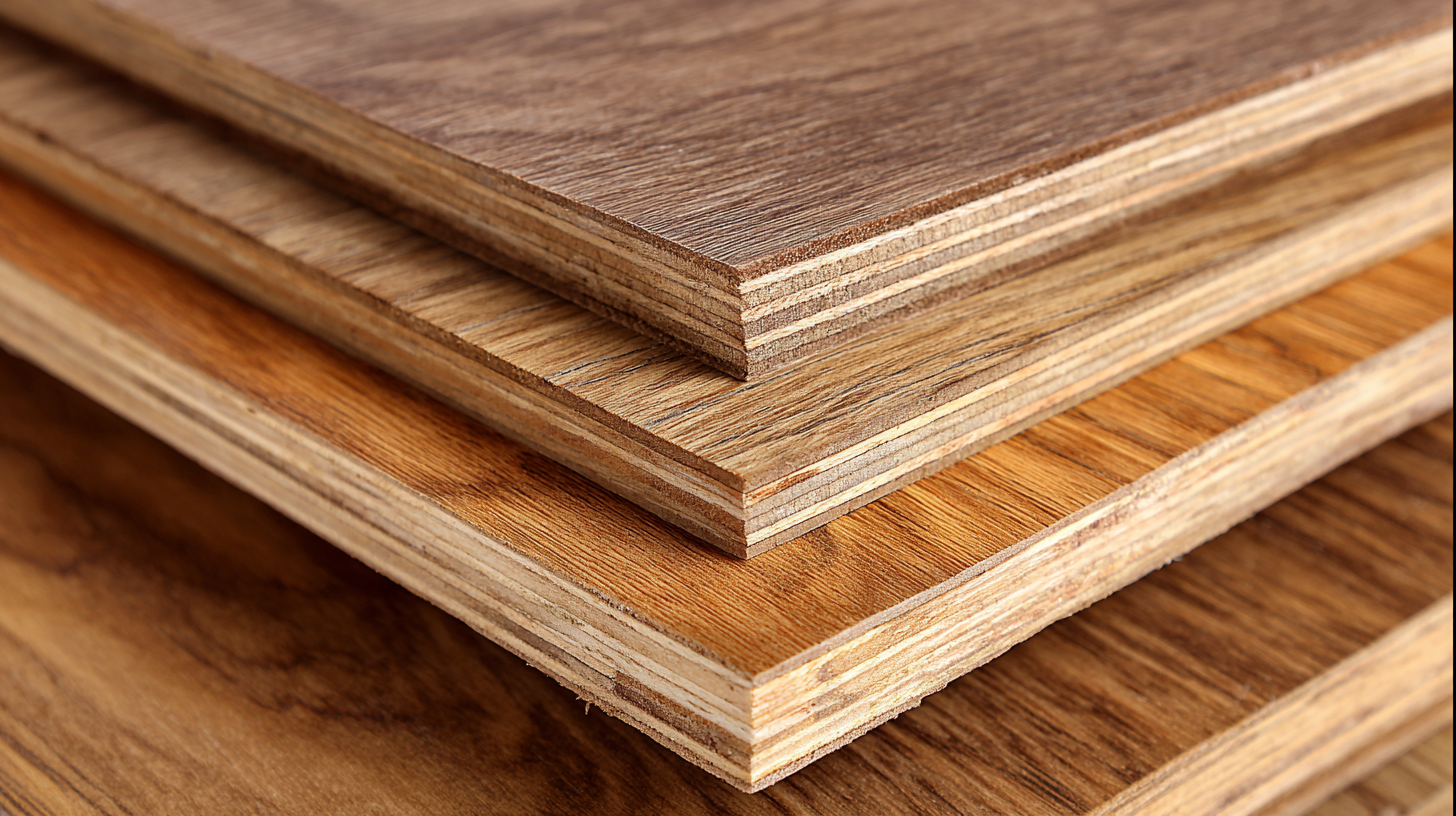

In recent years, the demand for prefinished plywood has surged, as more builders and designers recognize its numerous advantages and versatility in various applications. According to a report by the Wood Products Council, the global market for plywood is expected to reach USD 90 billion by 2025, with prefinished plywood accounting for a significant portion of this growth due to its ease of use and time-saving properties.

Prefinished plywood eliminates the need for additional finishing processes on-site, minimizing labor costs and project timelines. Furthermore, a study by the American Plywood Association highlights that using prefinished plywood can improve indoor air quality by reducing VOC emissions commonly associated with on-site finishing methods.

As architects and contractors increasingly prioritize sustainability and efficiency, understanding the benefits and applications of prefinished plywood is essential for anyone involved in construction and design.

Prefinished plywood is an increasingly popular choice among builders and designers seeking efficiency and quality in their projects. One of the key benefits of using prefinished plywood is the time savings it offers. With the finishing process completed before it arrives at the job site, contractors can focus on installation rather than preparation, significantly reducing labor costs and overall project timelines. This type of plywood is ready to use straight out of the box, allowing for quicker turnaround times without compromising on quality.

Additionally, prefinished plywood provides a consistent and superior finish. The factory-applied coatings are typically more durable and uniform compared to on-site applications, which can often be affected by environmental factors. This not only enhances the aesthetic appeal of the finished product but also ensures greater resistance to scratches, stains, and moisture. As a result, prefinished plywood is an ideal option for a variety of applications, including cabinetry, furniture, and architectural details, where both appearance and performance are paramount.

Prefinished plywood has become increasingly popular in modern construction and design due to its versatility and aesthetic appeal. This type of plywood is treated with finishes before it reaches the construction site, allowing for a faster installation process. Its diverse applications range from residential interiors, such as cabinetry and flooring, to commercial building facades and furniture design. By utilizing prefinished plywood, designers can achieve a polished look while minimizing labor costs and time on site.

Prefinished plywood has become increasingly popular in modern construction and design due to its versatility and aesthetic appeal. This type of plywood is treated with finishes before it reaches the construction site, allowing for a faster installation process. Its diverse applications range from residential interiors, such as cabinetry and flooring, to commercial building facades and furniture design. By utilizing prefinished plywood, designers can achieve a polished look while minimizing labor costs and time on site.

The advantages of prefinished plywood extend beyond just appearance. Its enhanced durability and resistance to moisture and wear make it suitable for high-traffic areas, ensuring longevity in various settings. Furthermore, as the push for sustainable materials continues, prefinished plywood stands out due to the efficient use of resources, as it often comes from managed forests. This makes it an eco-friendly option for environmentally conscious builders and designers looking to make a positive impact in their projects. As the construction industry embraces innovative materials, prefinished plywood is poised to play an essential role in shaping modern architectural landscapes.

When comparing prefinished plywood to traditional options, it's essential to consider their unique advantages. Prefinished plywood is crafted with a factory-applied finish, providing a consistent surface that reduces the need for on-site finishing. According to a report by the Wood Products Manufacturers Association, this can decrease labor costs by approximately 20-30%, making it an economical choice for builders and contractors. The controlled environment in which prefinished panels are produced also results in a more durable finish that is less susceptible to damage compared to traditional plywood, which often requires additional finishing steps.

Moreover, the environmental impact of prefinished plywood is another critical factor. A study by the Forest Stewardship Council highlighted that prefinished products utilize less material during the finishing process, reducing waste by up to 15%. This aligns with the growing consumer demand for eco-friendly building materials. Traditional plywood, while versatile, often entails more chemicals and processing, leading to a larger carbon footprint. The choice between these two options ultimately hinges on factors like cost, durability, and environmental consciousness, positioning prefinished plywood as a favorable alternative in today’s market.

When selecting prefinished plywood, it's essential to consider the specific needs of your project. The first step is to identify the intended use—whether it's for cabinetry, flooring, or wall paneling. Different applications will require varying levels of durability, moisture resistance, and aesthetic appeal. For instance, if you’re planning to use the plywood in a high-traffic area, opting for thicker sheets with a robust finish will enhance longevity and maintain appearance over time.

Another crucial factor is the type of wood and finish. Prefinished plywood comes in numerous varieties, including birch, maple, and oak, each offering unique grain patterns and colors. When selecting, consider the overall design theme of your space. Additionally, assess the factory finish quality; a higher quality finish will not only look better but will also resist scratches and stains more effectively, making maintenance easier. By carefully considering these elements, you can choose the right prefinished plywood that not only meets your functional requirements but also elevates the aesthetic of your project.

When it comes to maintaining prefinished plywood products, ensuring their longevity is crucial for optimal performance and aesthetics. One of the key aspects of care involves regular cleaning and the use of suitable cleaning agents. Avoid harsh chemicals that can damage the surface finish; instead, opt for mild detergents and warm water. Routine dusting with a soft cloth helps prevent scratches and keeps the finish looking new.

Additionally, understanding the environment where the plywood is installed can significantly impact its durability. High-moisture areas may require the integration of modern water-resistive barriers to further protect the plywood’s integrity. The introduction of innovative liquid-applied membranes offers enhanced protection against moisture, which is vital for prefinished plywood used in such conditions. By taking these precautionary measures and being mindful of the product's environment, you can ensure that your prefinished plywood retains its beauty and functionality for years to come.

Signup our newsletter to get update information, promotion or insight.