Plywood Direct is an innovative service in the plywood industry. It connects customers directly with manufacturers. This model reduces costs and offers faster delivery times. According to a report by Grand View Research, the global plywood market is expected to reach $80 billion by 2027, driven by rising construction activities.

Industry expert John Smith notes, "Plywood Direct represents a shift toward efficiency and better customer service.” This model aims to simplify the purchasing process. However, it raises questions about quality control and supplier reliability. Some buyers may worry about sourcing from unfamiliar manufacturers.

While Plywood Direct offers many benefits, potential drawbacks exist. Customers must conduct thorough research to ensure they purchase high-quality plywood. The balance between cost and quality remains a crucial concern. It is essential to find reliable sources within this direct model. Overall, Plywood Direct is reshaping the plywood landscape but requires thoughtful consideration from buyers.

Plywood Direct is an innovative concept in the construction and woodworking industries. It simplifies the process of purchasing plywood by connecting customers directly with suppliers. This model eliminates middlemen and often leads to better prices and quicker delivery.

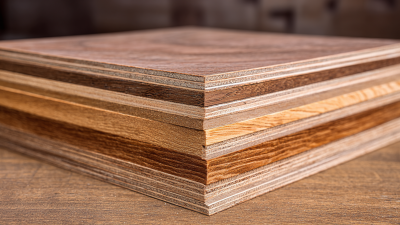

Customers can browse online platforms that showcase various types of plywood. Options vary from thickness to grade, catering to different project needs. Users appreciate the ease of comparing features and prices. However, some may struggle with deciding the right choice for their specific project. Not every piece of plywood meets the high expectations set by images online. Selecting the wrong type can lead to costly mistakes.

One significant advantage of Plywood Direct is the ability to customize orders. Some suppliers may offer cutting services, tailoring the plywood to match exact specifications. This can save time and effort on site. Yet, there are challenges. Quality inconsistency can occur, leading to unexpected results. Customers must inspect the material carefully upon delivery. Overall, while Plywood Direct promises efficiency, it requires thoughtful consideration to ensure project success.

Plywood Direct has come a long way since its inception in the early 20th century. Initially, plywood was a luxury item. It was primarily used in high-end furniture. Its complex manufacturing processes made it expensive. However, as demand grew, the industry evolved. The introduction of new machinery reduced production costs. Between 2010 and 2020, the global plywood market grew by 5.3% annually according to several industry reports.

In the past, plywood manufacturing relied heavily on manual labor. This has changed dramatically. Modern techniques use computer numerical control (CNC) machines. Such machines enhance precision and consistency. Data shows that nearly 70% of plywood production now utilizes automated methods. This shift has improved efficiency but raised concerns about jobs in the sector. The sustainability issue also looms large. Forest depletion due to plywood production is troubling. In 2022, it was reported that only 40% of global plywood came from sustainable sources.

The future of Plywood Direct rests on balancing efficiency with environmental responsibility. Innovations such as engineered wood products offer hope. These advancements may reduce waste and use fewer resources. Yet, reliance on technology must not overshadow the importance of sustainable practices. Reflection on these challenges is crucial for long-term success.

Plywood Direct is a unique approach to sourcing plywood. It simplifies the process, making it more accessible. Customers can easily navigate through various options. They can select based on thickness, type, and finish. This flexibility allows for tailored choices.

The operation starts with online browsing. Users can filter selections quickly. After finding the right product, they place an order. Then, the system confirms availability and timelines. This aspect can sometimes be slow. Users may need to wait longer than expected. It's a part of the process that requires patience.

Once the order is confirmed, the next step involves delivery. Plywood is packaged securely for transit. However, some packages may arrive damaged. Customers have the option to report issues. This feedback loop is vital for improvement. It's a continuous journey with ups and downs. The simplicity of Plywood Direct is its main strength, despite occasional challenges.

Plywood Direct offers numerous advantages for various projects. It provides an efficient way to access high-quality plywood directly from manufacturers. This eliminates middlemen, reducing costs. You can find different grades and thicknesses to meet various needs. The selection is vast, making it suitable for both large and small projects.

Using Plywood Direct also ensures faster delivery times. You can receive your materials without unnecessary delays. This quick access can be crucial for tight schedules. However, it's important to research the quality before purchasing. Sometimes, lower prices may come with trade-offs. Checking reviews or asking for samples can help avoid disappointment. Additionally, the platform may not always offer extensive customer support. Being prepared to troubleshoot is crucial. Consider your project requirements carefully before making a commitment.

| Feature | Description | Benefits |

|---|---|---|

| Sourcing | Direct access to plywood suppliers | Cost savings by eliminating middlemen |

| Variety | Wide range of plywood types and grades | Flexibility to choose materials for specific projects |

| Customization | Customized sizes and finishes available | Meets unique project specifications |

| Delivery | Direct delivery options to job sites | Streamlined logistics and reduced downtime |

| Support | Expert advice and project assistance | Improved project outcomes with professional guidance |

Plywood Direct offers a unique approach to sourcing plywood for various projects. Many industries rely on this versatile material. Its applications range from construction to furniture making. Plywood is favored for its strength and durability. It is lightweight yet sturdy, making it ideal for many uses.

In construction, plywood provides structural integrity. Builders often use it for walls, roofs, and flooring. It adapts easily to different shapes and sizes. In furniture making, plywood is popular for cabinets and shelves. Many artisans appreciate its aesthetic qualities. Plywood can be finished or painted to suit different designs.

However, there are considerations to keep in mind. Not all plywood is created equal, and quality can vary. Some may warp or not hold up over time. It's important to choose the right type for your needs. Reflect on how the material will be used. This will help ensure your project is a success.

Signup our newsletter to get update information, promotion or insight.