Birch plywood is a versatile material, favored by many woodworkers. Renowned expert James Fretwell once said, "Birch plywood blends durability with elegance." It's a unique choice for various projects, from furniture to cabinetry.

Using birch plywood can be both rewarding and challenging. Its fine grain and light color attract attention, but working with it requires skill. Many find it difficult to achieve clean cuts without splintering. Understanding how to manipulate this material is crucial for success.

When embarking on your project, remember to choose the right tools. A sharp blade can significantly improve your cuts. Pay attention to the grain direction as it can affect the finish. Birch plywood is beautiful but may sometimes test your patience. Embrace the journey, and your efforts will surely shine in the final product.

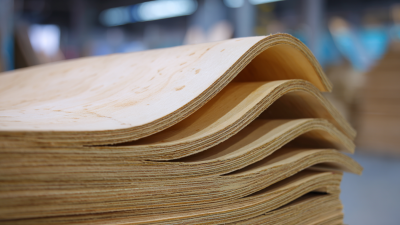

Birch plywood is renowned for its unique properties. Its fine grain and uniform surface make it desirable for many projects. This plywood type is strong yet lightweight, making it ideal for furniture and cabinetry. In fact, reports indicate that birch plywood has a tensile strength of over 50 MPa, contributing to its reputation for durability.

One key characteristic of birch plywood is its resistance to warping. When cut properly, it holds its shape well under different conditions. However, careful handling is necessary. Scratches can easily mar its finish. Many woodworkers feel that birch plywood requires a learning curve, especially when it comes to finishing techniques. A flawed finish can detract from the natural beauty of the wood.

Moisture resistance is another significant property. Birch plywood can withstand humidity better than many other types. Yet, end-grain sealing is often overlooked, leading to potential issues over time. Understanding these properties is crucial. Mistakes in application can undermine even the best projects. Taking the time to learn about birch plywood will pay off in successful creations.

Choosing the right thickness for your birch plywood project can greatly impact the final result. Think about the strength required for your build. Thicker plywood can hold more weight but may be overkill for lighter projects. For items like shelves or furniture, a thickness of 18mm often works well. However, smaller crafts or models might only need 6mm or 9mm.

Keep in mind that different thicknesses behave differently during cutting and assembling. Thinner sheets can bend easily and are less stable. This can lead to frustrating results if you aren't careful. Sometimes, it’s tempting to use a thicker sheet for everything. This can add unnecessary weight and complexity to your project.

Each thickness has its pros and cons, so consider your specific needs. You might find that experimenting with different sizes yields surprising outcomes. Don’t aim for perfection—sometimes a little flaw gives character to your piece. Reflect on your choices and adjust accordingly as you progress.

When working with birch plywood, having the right tools is essential. A quality circular saw is invaluable for making clean, straight cuts. Ensure your blade is sharp for best results. Using clamps can stabilize your plywood while cutting. This prevents movement and enhances precision. A jigsaw is great for intricate shapes. However, it can splinter the edges if not used carefully.

Measuring tools are also a must. A tape measure, square, and pencil will assist in marking accurate dimensions. Sanding tools come next. They help smooth rough edges, giving your project a polished look. Consider a hand sander for small areas or detail work. Additionally, wood glue is crucial for assembling pieces securely. Test the fit before gluing to avoid surprises later.

Don’t forget safety equipment, too. Safety glasses will protect your eyes from flying debris. Ear protection is wise when using power tools; they can be quite loud. Sometimes, you may find your project doesn’t come together as planned. Mistakes happen. Reflect on what went wrong and adjust your approach next time.

When working with birch plywood, safety is crucial. Begin with the right tools. A sharp circular saw or jigsaw ensures clean cuts. Dull blades can splinter the plywood, causing frustration. Adjust your speed when cutting. Moving too fast can lead to mistakes. Take your time.

Always wear safety gear. Goggles protect your eyes from debris. Dust masks help with the fine particles floating around. It’s easy to overlook these, but they make a difference. After cutting, sand the edges. This process smooths out imperfections and reduces snagging. Use a fine-grit sandpaper for the best finish.

Measuring twice is not just a saying. Mistakes in measurement can waste material. Always double-check dimensions before cutting. This habit will save time and resources. Test cuts on scrap pieces help. They offer a chance to adjust settings and techniques. Remember, birch plywood is forgiving but needs respect. Each piece is unique, with its own quirks. Embrace the process and learn from any mishaps.

Finishing birch plywood properly is essential for ensuring its durability. Start with sanding the surface. Use fine-grit sandpaper for a smooth finish. This prepares the plywood for staining or sealing. Remember, a consistent finish starts with good prep work. Don’t rush this process. Pay attention to the corners and edges. They can easily be overlooked but are visibly important.

Choosing the right finish affects longevity. A clear varnish can protect the surface. However, test it on a small piece first. Sometimes, the finish can darken the plywood more than desired. A natural oil finish can provide protection while enhancing the grain. This option is less glossy and gives a more organic feel. Take time to apply several thin coats for the best results.

Be mindful of environmental factors affecting your project. Humidity and temperature can alter the finish. In humid areas, the plywood may absorb moisture, warping the structure. Regular maintenance is necessary to preserve its look. A simple wipe down can prevent dirt buildup. However, avoid soaking the plywood in water. Reflect on your approach. Each project teaches something new about materials. Stay curious. Each piece of wood has a story waiting to be revealed.

Signup our newsletter to get update information, promotion or insight.