When embarking on a construction or crafting project, selecting the right materials is crucial for achieving optimal results. Among the various options available, half inch plywood has emerged as a popular choice due to its versatility, strength, and cost-effectiveness. According to the U.S. Forest Products Laboratory, plywood's unique laminating process gives it superior structural properties compared to traditional solid wood, making it a preferred material in both residential and commercial applications. Reports from the National Wood Council indicate that in 2022, the demand for plywood, particularly half inch thickness, increased by over 15% as builders and DIY enthusiasts recognized its myriad benefits.

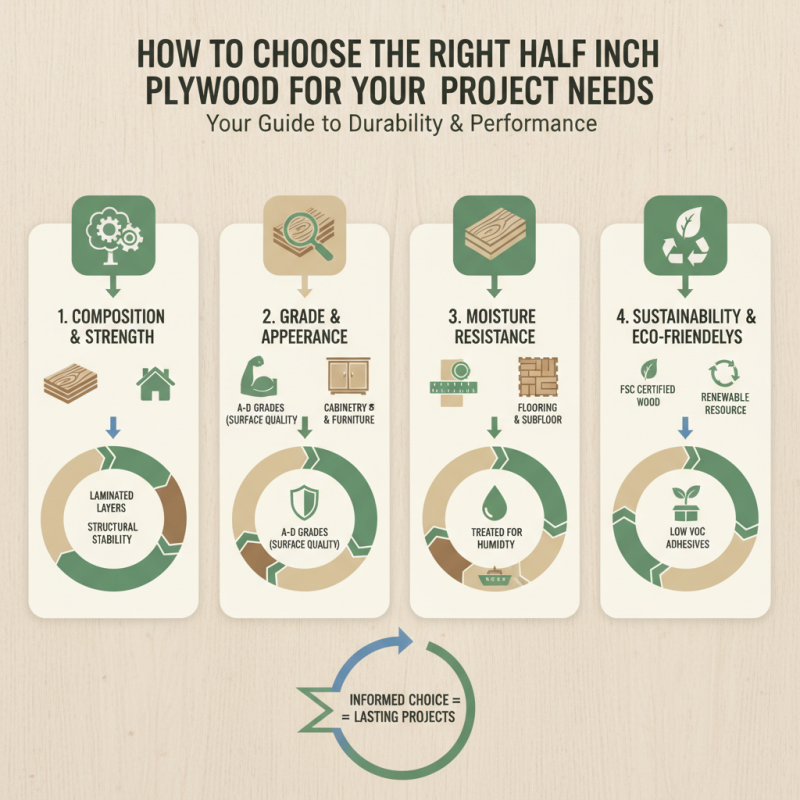

Choosing the right half inch plywood involves more than just picking a sheet off the shelf; understanding its composition, grade, and moisture resistance is essential for ensuring durability and performance in your specific project. Industry experts note that the grade of plywood can significantly affect its strength and appearance, impacting everything from cabinetry to flooring. Furthermore, the increasing emphasis on sustainability in construction has led to a rise in the availability of eco-friendly half inch plywood options, meeting both aesthetic and environmental standards. By making informed decisions based on these considerations, project leaders can enhance their outcomes, ensuring that their projects are built to last.

When it comes to selecting half inch plywood for your project, it’s essential to understand the various types available to ensure you make the right choice. Half inch plywood typically comes in different grades, each suited for specific uses. For instance, A-grade plywood has a smooth surface with few imperfections, making it ideal for visible parts of furniture or cabinetry. Conversely, C-grade plywood may have more knots and blemishes, which is suitable for structural work or projects that will be painted over.

Tips: Always check the grading system when purchasing plywood, as it will guide you in choosing the best option for your project’s aesthetic and functional requirements. Additionally, consider the type of veneer; hardwood plywood is an excellent option for sophisticated finishes, while softwood plywood is perfect for framing and workshop projects.

Different types of half inch plywood also include marine-grade and exterior plywood, designed to withstand moisture. These are crucial for projects located in humid environments or for outdoor furniture. Selecting the right type not only increases the durability of your project but also enhances its appearance.

Tips: If you're working on outdoor projects, ensure you’re purchasing plywood specifically rated for exterior use, as this will prolong the life of your construction. Furthermore, investing in quality plywood can lead to better long-term savings by minimizing repair and replacement costs.

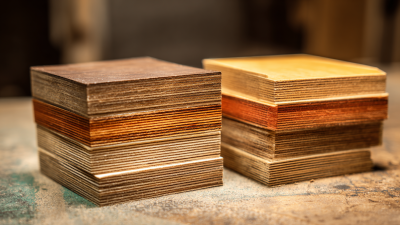

When evaluating the strength and durability of half inch plywood for your project needs, it’s crucial to consider the material's structural properties. Half inch plywood typically consists of multiple layers (or plies) of wood veneer, which are glued together in such a way that the grain of each layer runs in different directions. This cross-lamination enhances the panel's strength and resistance to warping, making it a popular choice for various applications, from cabinetry to subflooring.

According to the APA – The Engineered Wood Association, properly manufactured plywood can exhibit shear strengths of up to 1,400 psi, which is essential for load-bearing applications.

Tips: When selecting half inch plywood, pay close attention to the grading of the plywood. Higher grades (like A or B) will have fewer imperfections and offer better durability. Additionally, consider the type of adhesive used in the plywood; exterior-grade adhesives provide added resistance to moisture, which is particularly beneficial for projects exposed to humidity.

Moreover, the intended use of the plywood will influence the choice significantly. For projects requiring high strength, such as structural framing or flooring, it is recommended to select a plywood with higher shear strength ratings. On the other hand, decorative projects may prioritize aesthetic quality over structural integrity.

According to industry analyses, a well-chosen half inch plywood can offer a lifespan exceeding 20 years, provided that it is used in the appropriate context and with proper maintenance.

When selecting half-inch plywood for your project, one of the most critical factors to consider is its environmental impact and sustainability. The plywood industry has made strides in adopting more sustainable practices, especially in sourcing timber. According to a report by the Forest Stewardship Council (FSC), sustainable forestry practices can reduce deforestation rates by up to 30%. This shift toward responsibly sourced wood can significantly influence carbon emissions, as wood from sustainably managed forests helps maintain biodiversity and minimizes disruption to ecosystems.

Furthermore, the choice of adhesives and finishes used in plywood production is vital for environmental health. Many traditional adhesives contain formaldehyde, which poses risks both to human health and the environment. The U.S. Environmental Protection Agency (EPA) indicates that products with low or no-VOC (volatile organic compounds) adhesives can significantly reduce indoor air pollution. By opting for plywood certified under the California Air Resources Board (CARB) standards, consumers can ensure they are selecting a healthier option for both indoor and outdoor applications that aligns with sustainability goals.

As the demand for sustainable building materials grows, awareness regarding the lifecycle of plywood is essential. Reports indicate that choosing plywood made from reclaimed or recycled materials can contribute to a circular economy, where materials are reused rather than discarded. With an estimated 60 million tons of wood waste produced in the U.S. alone each year, utilizing reclaimed plywood not only reduces waste but also lessens the reliance on virgin materials, promoting a more sustainable construction landscape.

When selecting half-inch plywood for your project, the finish and surface treatment play a crucial role in determining not only the aesthetics but also the durability and functionality of the material. According to industry reports, around 42% of construction professionals indicate that improper finish selection can lead to premature wear and tear, affecting the lifespan of the plywood. This highlights the importance of choosing a finish that aligns with the use case—be it for furniture, cabinetry, or structural applications.

One popular treatment method is sealing plywood with water-resistant coatings, which can enhance its performance in high-humidity environments. Research shows that treated plywood can withstand water exposure for over 24 hours without significant damage, compared to untreated options that might show signs of deterioration within just a couple of hours. Additionally, finishes such as varnish or polyurethane not only protect the plywood from moisture but also from scratches and UV rays, ensuring the wood retains its appearance over time. Thus, careful consideration of surface treatment is essential for maximizing the integrity and longevity of half-inch plywood in your projects.

When sourcing half inch plywood for your projects, quality should be your top priority. Start by looking for reputable suppliers with a strong history of providing high-quality materials. It can be beneficial to visit local lumberyards or home improvement stores where you can inspect the plywood personally. Pay attention to the grading of the plywood, which indicates its quality and suitability for various applications. Higher-grade plywood will typically have fewer defects, making it a better choice for projects that require a smooth finish or structural integrity.

Another essential tip is to consider the wood species used in the plywood. Different species offer varying levels of durability and aesthetics. For example, hardwood plywood tends to be stronger and more visually appealing, while softwood plywood may be more cost-effective for certain projects. Additionally, check for certifications that indicate sustainable sourcing, such as the Forest Stewardship Council (FSC) label. This not only ensures you're getting quality plywood but also supports environmentally friendly practices. Comparing prices and quality among various suppliers will help you make an informed choice that meets your project needs while ensuring you're investing in durable materials.

Signup our newsletter to get update information, promotion or insight.