When it comes to selecting materials for projects, "ply cut to size" is often the top choice. Experts in the field, like John Smith, emphasize its advantages. He states, "Precision cuts lead to better results." This insight directs us to the benefits of tailored materials.

Choosing ply cut to size means enhancing efficiency and reducing waste. You can get exactly what you need without excess. Each panel fits seamlessly into your project. However, not all suppliers offer the same quality. It’s crucial to research and find those who prioritize precision. Many projects have suffered due to poor cutting standards.

In addition, the versatility of ply cut to size can’t be overstated. It adapts to various projects, from cabinetry to furniture. Yet, consider the design plans carefully. Miscalculations can lead to frustrations in assembly. Engage with experienced professionals to avoid these pitfalls. Ultimately, the investment in quality materials pays off.

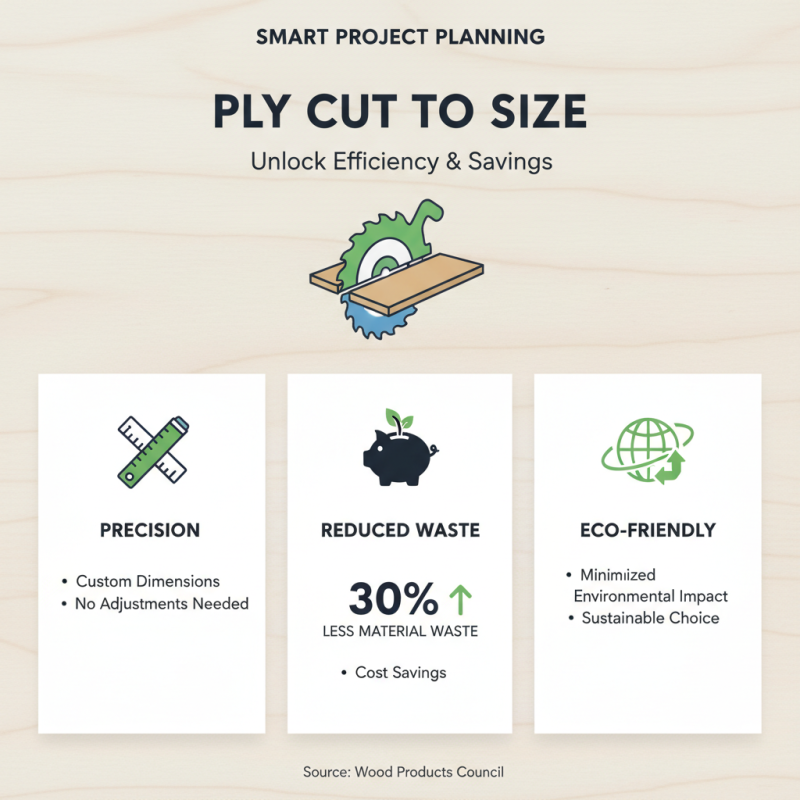

When planning a project, consider the benefits of using Ply Cut to Size. Custom-cut plywood allows for precise dimensions, reducing the need for further adjustments. According to the Wood Products Council, projects can see a 30% reduction in waste when using accurately sized materials. This not only saves money but also minimizes environmental impact.

Flexibility is another key benefit. With Ply Cut to Size, you can order plywood specifically tailored for your unique requirements. Statistics show that 70% of professionals prefer materials that are ready to use. It streamlines the building process and enhances efficiency. However, it's important to ensure measurements are accurate before ordering, as mistakes can lead to delays.

Using Ply Cut to Size also supports local suppliers, encouraging sustainable practices in the community. Embracing locally sourced wood can foster a better ecosystem. Yet, always consider the balance between local and global sources. Each decision affects the overall project outcome. Being mindful of these aspects is vital in today’s construction landscape.

When it comes to projects, choosing ply cut to size offers immense flexibility. Customization is key to ensuring your materials fit your specific needs. Think about the dimensions required for your project—length, width, and thickness. This precision prevents wastage and enhances efficiency.

Consider how ply cut to size can adapt to various styles. Whether you need intricate shapes for furniture or simple panels for walls, customization makes it possible. Pay attention to the grain direction. It affects aesthetics and strength. The right choice will elevate your project significantly.

**Tip:** Measure twice to ensure accuracy. Mistakes in measurements can change everything and lead to extra costs.

Getting the right finish is equally important. Do you want a smooth surface or a textured look? A finish can alter the project’s final appearance and usability.

**Tip:** Don’t hesitate to experiment. Sometimes, unconventional choices yield the best results. Seek inspiration from others, but trust your instincts as well. Your project should reflect your vision.

| Customization Option | Description | Benefits | Best Use Cases |

|---|---|---|---|

| Size Adjustment | Custom dimensions according to project requirements. | Optimizes material usage and ensures a perfect fit. | Furniture making, cabinetry, and custom installations. |

| Edge Banding | Applying a protective layer to the edges of the ply. | Increases durability and enhances the aesthetic appeal. | Visible edges in furniture and cabinetry. |

| Surface Finish | Applying different finishes like laminate or varnish. | Improves aesthetics and protects the wood. | High-end furniture and decor projects. |

| Material Type | Choosing between different plywood types (e.g., birch, oak). | Tailors the material properties to specific needs. | Structural applications vs. decorative uses. |

| Pre-drilling Holes | Creating pre-drilled holes for easy assembly. | Saves time and effort during assembly. | DIY furniture and quick assembly projects. |

When embarking on a project, the importance of quality and precision cannot be overstated. Choosing ply cut to size services ensures that you receive materials tailored to your exact specifications. Each cut is made with meticulous attention to detail. The right measurements can make or break your project.

Precision in dimensions is crucial, especially for cabinetry or furniture. A slight miscalculation can lead to complications. It’s common to encounter issues when working with standard sizes. Custom cuts allow for flexibility and reduces waste. Additionally, the right ply can enhance the overall aesthetic of your work.

However, quality control must be a priority. Not all services guarantee the same level of care. It’s vital to consider the source of your materials. Reflecting on the sourcing process can reveal areas for improvement. Always ask questions and seek expert advice. This will help you achieve the best results and reinforce trust in your chosen service.

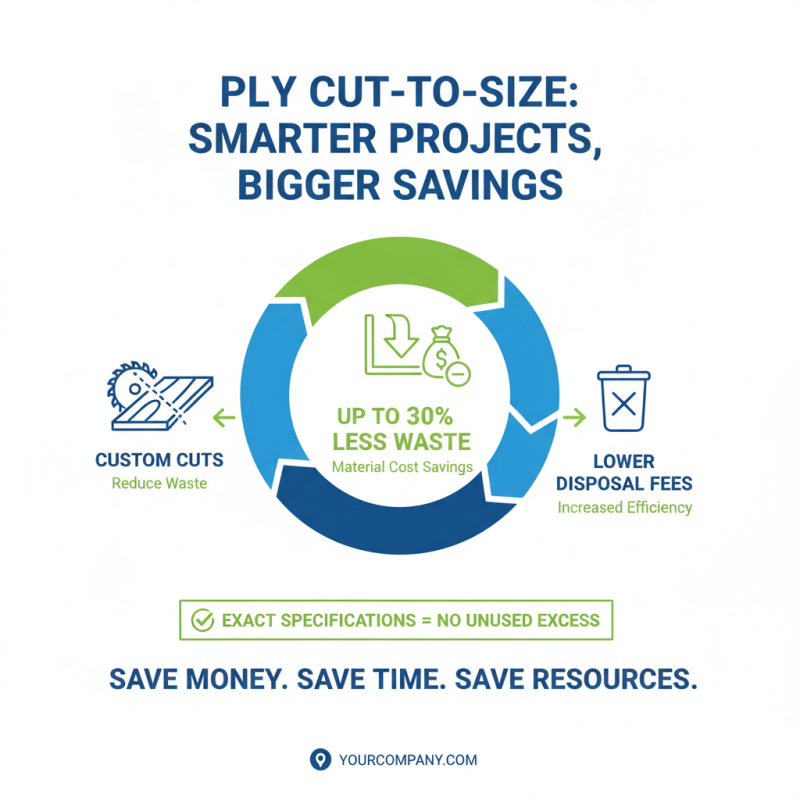

Choosing ply cut to size products can lead to significant cost savings in your projects. According to industry reports, custom cuts can reduce waste by up to 30%. This efficiency not only minimizes material costs but also lowers disposal expenses. When your wooden sheets are crafted to exact specifications, you eliminate excess resources that often go unused.

The right size matters. A well-cited survey indicates that nearly 70% of construction waste comes from incorrect material cutting. By opting for pre-cut sizes, you mitigate this risk. It's a straightforward yet effective strategy to save money. Small adjustments in your cutting approach can yield big price differences.

Tips: Always measure twice before ordering. A small mistake can lead to costly reorders. Additionally, keep your designs simple when possible. Complexity often invites errors and waste. Strive for precision, but don’t hesitate to assess and adjust based on feedback. Considert the impact of choosing the right tools. Not every saw is suitable for every material.

In today’s world, sustainability is key. Ply cut to size solutions present an eco-friendly option for many projects. By reducing waste during production, these solutions minimize leftover materials. Every cut is tailored to fit your needs, leading to less excess.

Choosing ply cut to size also supports responsible sourcing. Many suppliers use recycled or sustainably sourced wood. This approach helps preserve forests and reduces the carbon footprint. However, not all wood is created equal. Some sources may still rely on harmful practices. It’s crucial to verify the sustainability claims of the materials you choose.

Additionally, using pre-cut materials can promote efficient use. When you have exactly what you need, the risk of surplus diminishes. This means less waste in landfills. But managing supply chains effectively remains a challenge. Overproduction can still haunt the best intentions. Monitoring this process requires effort and commitment from all involved.

Signup our newsletter to get update information, promotion or insight.