When embarking on a building project, selecting the right materials is crucial to ensure durability, functionality, and aesthetic appeal. One outstanding choice that frequently comes to the forefront is marine plywood sheets. Renowned for their resilience and water resistance, these sheets are specifically designed to endure harsh marine environments, making them an ideal option for various construction applications, from boat building to outdoor structures.

Marine plywood sheets are crafted using high-quality hardwood veneers that are bonded together with waterproof adhesive, which effectively prevents delamination and other issues caused by moisture exposure. This unique construction not only reinforces the structural integrity of the material but also extends its lifespan, making it a cost-effective investment for builders and contractors looking for reliability in their projects.

Furthermore, the versatility of marine plywood sheets allows for a wide range of uses beyond traditional marine applications. Their strength and aesthetic qualities make them suitable for both commercial and residential construction, providing endless possibilities for creative architectural designs. By choosing marine plywood sheets for your next building project, you are ensuring a solid foundation that promises long-lasting performance and exceptional value.

Marine plywood is specifically designed for applications where moisture exposure is a concern, making it an ideal choice for various construction projects. The composition of marine plywood consists of multiple layers of thin veneer, typically sourced from high-quality hardwoods like Okoume or Meranti. These veneers are bonded together using waterproof adhesives that significantly enhance durability and resistance to water damage. According to a report by the Plywood & Engineered Wood Products Association, marine plywood has a moisture resistance level that can be as high as 60%, making it suitable for environments such as boat construction, docks, and outdoor facilities.

In addition to its moisture-resistant properties, marine plywood is recognized for its strength and flexibility. The dense core and layered construction provide superior structural stability, allowing it to withstand heavy loads while also offering enhanced resistance to warping. The American Institute of Timber Construction indicates that marine plywood can have a tensile strength of up to 30% more than standard plywood, making it a preferred choice for both residential and commercial applications where long-lasting performance is essential. This unique combination of properties not only extends the lifespan of projects but also improves their overall safety and reliability in adverse weather conditions.

Marine plywood is an excellent choice for construction projects, particularly in environments prone to moisture and weather fluctuations. This type of plywood is engineered to withstand extreme conditions thanks to its unique waterproof adhesive and resilient veneer layers. According to a 2021 report by the Global Plywood Market Analysis, marine plywood is estimated to have a market growth rate of 5.1% annually, highlighting its rising popularity among builders who seek durability and longevity.

One of the primary benefits of using marine plywood in construction is its remarkable resistance to rot and fungal growth. A study conducted by the American Plywood Association demonstrates that marine plywood, when subjected to moist conditions, shows a failure rate significantly lower than that of standard plywood grades. This durability not only extends the lifespan of structural elements but also reduces long-term maintenance costs. Builders can rest assured that they are investing in materials that will withstand the test of time, particularly in coastal or high-humidity areas.

Additionally, marine plywood offers enhanced strength and stability, which is essential for constructing high-quality projects like boat building, docks, and other structures exposed to water. The International Journal of Construction and Building Materials reports that marine plywood can provide better structural performance under heavy loads while maintaining its shape under temperature fluctuations. This reliability makes it a preferred material among architects and engineers who prioritize safety and structural integrity in their designs.

| Feature | Benefit | Application |

|---|---|---|

| Water Resistance | Prevents structural damage due to moisture | Boat building and humid environments |

| Durability | Longer lifespan compared to standard plywood | High-traffic areas and outdoor furniture |

| Versatility | Can be used in a variety of applications | Marine, residential, commercial projects |

| Aesthetic Appeal | Beautiful wood grain finish enhances designs | Interior design and decorative projects |

| Strength | High strength-to-weight ratio for efficient builds | Framing and structural applications |

Marine plywood is specifically designed to withstand moisture and is treated to resist decay, making it an ideal choice for construction projects in marine environments or areas exposed to high humidity. Unlike standard plywood, which typically consists of layers of wood veneer glued together with adhesives that may not withstand wet conditions, marine plywood is manufactured using waterproof adhesives. According to a report by the Plywood Association, marine plywood can offer strength and durability that often exceed that of typical exterior-grade plywood, providing a longer lifespan in challenging environments.

When comparing marine plywood to other types, such as hardwood or softwood plywood, one significant factor is the thickness and density of the layers. Marine plywood usually features higher-quality wood veneers that are typically more consistent in thickness and density, contributing to its superior structural integrity. A study published by the International Journal of Wood Science highlighted that the shear strength of marine plywood was 20-30% higher than that of standard plywood options, making it the preferred material for applications that require exceptional strength and resilience, such as boat building and waterfront constructions. This strength-to-weight ratio is crucial for optimizing structural performance without excessive bulk, which can lead to increased costs and logistical challenges in construction projects.

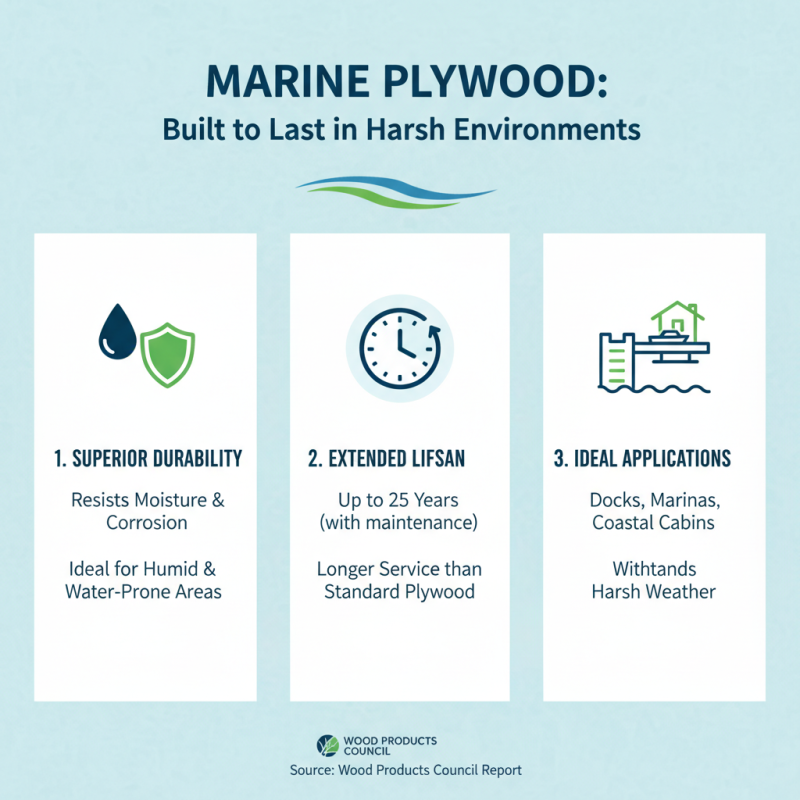

Marine plywood sheets are an ideal choice for various building applications due to their superior durability and resistance to moisture and corrosion. This makes them particularly suitable for projects in humid or water-prone environments. According to a report by the Wood Products Council, marine plywood boasts a longer lifespan compared to standard plywood, offering up to 25 years of service when properly maintained. This longevity is essential for structures that are exposed to harsh weather conditions, such as docks, marinas, and coastal cabins.

In addition to marine construction, these plywood sheets are increasingly recommended for innovative architectural solutions, including the construction of curved and floating structures. Their structural integrity allows for versatile design options without compromising stability. The use of marine plywood is also expanding in furniture design, particularly in environments like outdoor cafes and restaurants, where exposure to the elements is a concern. Research indicates that using high-quality marine plywood in these applications can reduce the frequency of repairs and replacements by up to 40%, showcasing its cost-effectiveness over time.

As the construction industry moves towards sustainable practices, marine plywood is a favorable option. It is often manufactured from sustainably sourced wood, aligning with eco-friendly building standards. This trend is reflected in the growing demand for marine plywood, which is projected to increase by 6% annually, driven by the rise in construction activities in waterfront areas. Thus, choosing marine plywood not only enhances durability but also supports eco-conscious building initiatives.

When it comes to enhancing the longevity of marine plywood, proper maintenance is crucial. One of the primary tips for maintaining marine plywood is to keep it regularly sealed and coated with a high-quality marine varnish or epoxy resin. This protective layer acts as a barrier against moisture and UV damage, which are significant threats to the integrity of the plywood. Applying a fresh coat annually, particularly before the rainy season or extended exposure to harsh weather, ensures that the plywood remains in prime condition, thus extending its lifespan significantly.

Another essential maintenance tip is to keep the surface clean and free from debris. Regularly washing the plywood with mild soap and water removes salt, dirt, and grime that can lead to deterioration over time. Additionally, inspecting the plywood for signs of wear and addressing any issues—such as cracks, warping, or peeling—immediately can prevent small problems from escalating into significant repairs. By following these maintenance practices, you can ensure that your marine plywood continues to perform well in demanding environments, whether it's for boat construction or waterfront structures.

Signup our newsletter to get update information, promotion or insight.