Birch plywood 18mm is an excellent choice for various DIY projects. Its strength and versatility make it popular among woodworkers. When working with this material, achieving perfect results involves understanding its unique properties.

Each project requires careful planning and execution. Mistakes can happen, such as miscalculating dimensions or uneven cuts. These errors can impact the durability and appearance of your final piece. It's essential to learn from these experiences and make necessary adjustments for better outcomes.

To truly harness the potential of birch plywood 18mm, embrace the details. Consider the grain, finish, and joinery techniques. Each choice plays a critical role in the durability and aesthetics of your project. A little extra attention can lead to impressive results.

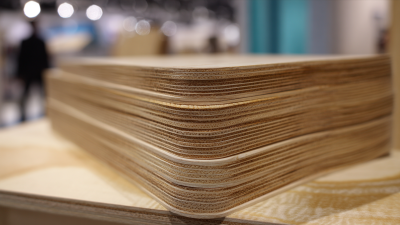

Birch plywood is known for its strength and versatility. The 18mm thickness provides durability for various projects. Its smooth surface allows for easy finishing, making it ideal for furniture and cabinetry. This plywood type can withstand stress well. However, it may be prone to dents and scratches, which can be frustrating during use.

Understanding the properties of 18mm birch plywood is crucial. Its fine grain gives an attractive appearance. Yet, flaws in the sheet may disrupt your plans. When cutting, ensure your tools are sharp. A dull blade can result in rough edges, causing more work later. Sanding might not completely fix these imperfections, leading to surface quality issues.

The benefits of 18mm birch plywood extend to its weight. It is lighter than hardwood, making it easier to handle. Nonetheless, take caution while moving large sheets; they can flex unexpectedly. Working with this material can spark creativity but may also test your patience. Strive for precision, but embrace small mistakes as learning opportunities in your crafting journey.

When working with 18mm birch plywood, choosing the right tools can significantly enhance your project. A sharp circular saw is essential for clean cuts. Ensure you have blades designed for plywood. They minimize tear-out and give a smoother finish. A jigsaw is also useful for intricate shapes but requires a steady hand. It’s easy to make mistakes if you rush.

Drills should have high-quality bits that can handle wood without splintering. Pay attention to your drill speed. Too fast can lead to overheating and damage. Clamps are crucial to hold pieces steady while cutting or drilling. A solid setup can prevent accidents or misalignments. Remember to double-check measurements before making any cuts. Accuracy is vital.

Even with the best tools, you may encounter setbacks. Not every cut will be perfect, and adjustments are often needed. Learning to adapt is part of the process. Tools can wear out or break, requiring reflection on your approach and technique. Making mistakes can be frustrating, but they often teach valuable lessons. Each project is an opportunity to improve your skills with birch plywood.

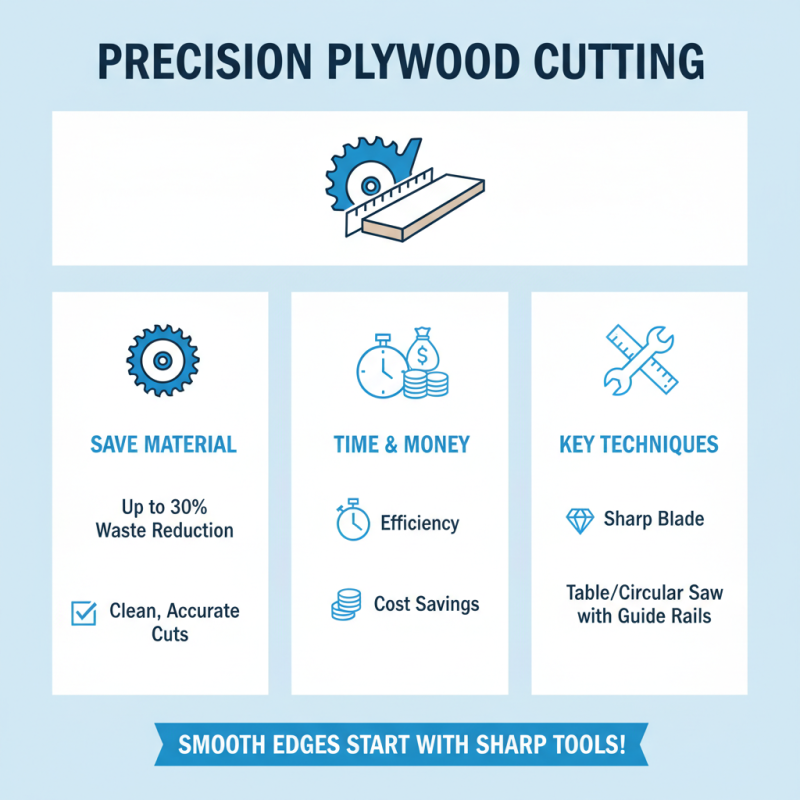

Cutting 18mm birch plywood requires precision and attention to detail. Industry reports indicate that improper cutting can lead to nearly 30% material waste. Ensuring clean, accurate cuts can save both time and money in any project. A sharp blade is crucial to achieving smooth edges, and it is recommended to check your tools regularly. Using a table saw or a circular saw with guide rails can drastically improve accuracy.

Another important aspect is the cutting technique. Many craftsmen underestimate the importance of speed and pressure when cutting plywood. A slow, steady approach ensures control, while excessive force can splinter the wood. Interestingly, studies show that around 15% of professional errors result from poor technique. Always measure twice and use clamps to secure your plywood, preventing movement during the cut.

When it comes to layout, plan your cuts carefully. Mark your lines clearly, even if it feels like extra work. Taking the time to create a detailed cutting plan can help avoid regrettable mistakes. Many artisans find that a poorly planned cut often leads to scrap pieces that cannot be utilized. Embrace the learning curve; every imperfect cut is an opportunity to refine your skills.

When working with 18mm birch plywood, finishing options are crucial. Studies show that properly finished surfaces can enhance durability by up to 40%. A basic polyurethane coat can provide a protective layer, safeguarding against moisture and wear. Yet, improper application can lead to bubbles or uneven surfaces. Consider testing your finish on a scrap piece first.

Choosing the right finish impacts both appearance and longevity. Clear sealants can enhance the natural beauty of birch, showcasing its grain. However, some may yellow over time, which could alter the project's look. Always remember that surface preparation is vital. Sanding must be thorough to ensure an even finish. Failing to do this can result in patches where the finish does not adhere well, leading to peeling or flaking.

For added protection, explore oils like tung or danish. These penetrate deeply, providing a durable finish that resists moisture effectively. Yet, they require frequent reapplication. Reflect on how often you want to maintain your project. The right choice balances aesthetics with practical upkeep, a detail that can shape the lifespan of your work.

When working with 18mm birch plywood, being mindful of common mistakes can improve your projects significantly. One frequent error is not measuring accurately. Ensure all cuts are precise. A slight mistake can lead to mismatched pieces. Use a reliable measuring tape for consistency.

Another common issue is inadequate surface preparation. Sanding is crucial to avoid splintering. An unfinished edge can ruin the overall appearance. A few strokes with sandpaper can make a big difference. Don't skip this step, even if it seems tedious.

Remember to choose the right adhesive. Some cements work better with plywood than others. Experiment with different options to find the best bond. Avoid rushing this part of the process. Rushing can lead to weak joints or uneven surfaces. Taking the time to reflect on these elements will yield better results.

| Tip/Usage | Common Mistake | Solution/Advice | Expected Outcome |

|---|---|---|---|

| Choose quality plywood | Using inferior materials | Invest in high-grade birch plywood | Durable and aesthetically pleasing projects |

| Measure accurately | Skipping measurements | Always double-check dimensions before cutting | Better fitting pieces and fewer mistakes |

| Use the right tools | Using improper cutting tools | Select blades specifically for plywood | Cleaner cuts and reduced splintering |

| Practice good sanding techniques | Neglecting surface preparation | Sand before finishing to achieve a smooth surface | Professional-looking finish and better adhesion |

| Seal edges and surfaces | Ignoring moisture protection | Apply an appropriate sealant for protection | Increased longevity of the project |

| Test finishes on scrap pieces | Applying finishes directly onto the project | Always test on leftover plywood | Desired appearance and finish consistency |

| Follow manufacturer’s instructions | Ignoring guidelines on products | Read all instructions before usage | Optimal performance and results |

Signup our newsletter to get update information, promotion or insight.