Birch plywood has gained significant attention in the woodworking industry. Its unique properties make it a desirable choice for many applications. “Birch plywood combines strength and beauty,” says John Smith, an expert in sustainable materials. This quote encapsulates why so many people prefer it.

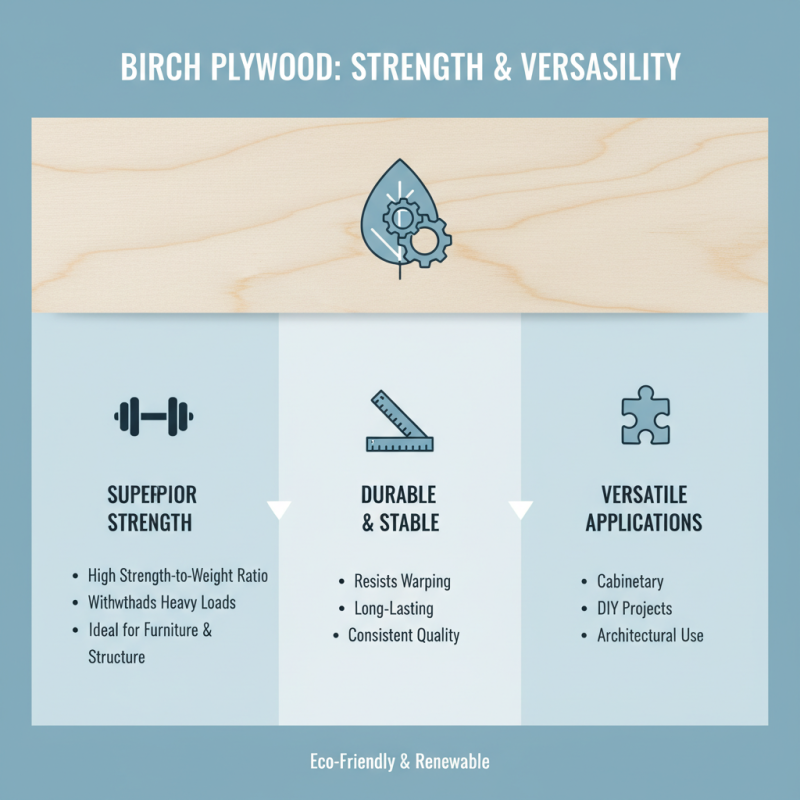

The appeal of birch plywood lies in its exceptional strength-to-weight ratio. This makes it ideal for furniture, cabinetry, and even musical instruments. Its fine grain and light color also add aesthetic value, which attracts designers and builders alike. However, not all birch plywood is created equal. Some products may use inferior materials, potentially compromising quality.

Moreover, birch plywood is often praised for its sustainability. Yet, some challenges exist in sourcing. Overharvesting in certain areas can raise concerns. It’s crucial to balance demand with responsible forestry practices. As the popularity of birch plywood continues to grow, we must reflect on its impact on the environment and industry.

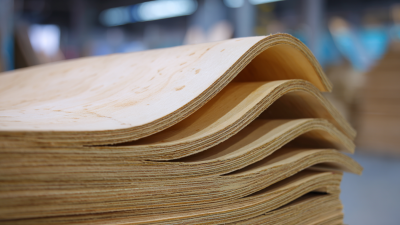

Birch plywood is a versatile material made from birch tree layers. Each layer is thin and glued together. This gives the plywood strength and durability. Birch trees grow in many regions, particularly in Europe and North America. They are known for their straight grain and fine texture. This enhances the wood’s aesthetic appeal.

The composition of birch plywood varies. It typically consists of three to seven layers, also known as veneers. Each layer is cross-banded to improve stability and reduce warping. According to industry reports, birch plywood has a high strength-to-weight ratio. This makes it ideal for furniture and cabinetry. However, its sourcing raises some concerns. Sustainability and ethical practices in logging need constant attention.

Moreover, the cost of birch wood fluctuates. Market demand affects availability. Some manufacturers face challenges in sourcing quality birch veneers. In certain regions, this can lead to shortages. The rise in environmentally friendly materials brings both opportunities and challenges for birch plywood. Balancing quality, cost, and sustainability remains crucial for continued popularity in the market.

Birch plywood is created through a meticulous manufacturing process. It starts with selecting high-quality birch logs. These logs are debarked and sliced into thin veneers. Typically, several layers of veneers are glued together at right angles. This cross-laminating enhances strength and stability. The gluing process is vital; the adhesives used must be durable to withstand moisture and usage.

The production process involves strict quality control. According to industry reports, around 80% of birch plywood is produced in Europe and North America. Each sheet undergoes heat and pressure treatment. This step removes excess moisture and ensures a perfect bond. Yet, not all methods guarantee consistent quality. Some manufacturers use less robust adhesives, leading to issues like warping or delamination over time.

Birch plywood's versatility stems from its finishing options. It can be left plain or coated with various stains and varnishes. Each finish has distinct aesthetic qualities, impacting its popularity in design. Despite its many advantages, manufacturers must address the environmental impact of sourcing birch. Sustainable logging practices are crucial for long-term supply. The balance between quality, aesthetics, and sustainability presents an ongoing challenge in the industry.

Birch plywood has gained popularity for various reasons. One of the main advantages is its strength-to-weight ratio. Studies indicate that birch plywood is significantly stronger than other hardwood plywood options. It can withstand heavy loads, making it ideal for furniture and structural applications.

Another benefit is its aesthetic appeal. Birch plywood has a fine, even grain that provides a smooth finish. This enhances its suitability for visible applications, such as cabinetry and wall panels. According to industry reports, birch plywood retains its look well over time compared to alternatives.

Cost-effectiveness is also key. While birch plywood is priced higher than softwood, its durability can offset the initial costs. In many cases, users find they save money in the long run due to its lifespan. However, some may struggle to source high-quality birch plywood. This can affect project timelines. It's essential to consider these factors when selecting materials.

Birch plywood is gaining traction across various industries due to its versatility and strength. In furniture manufacturing, birch plywood is favored for its smooth finish and aesthetic appeal. According to a recent report, the global furniture market's demand for engineered wood, including birch plywood, is projected to grow by 5% annually through 2026. This growth is attributed to the increasing preference for sustainable materials.

In the automotive sector, birch plywood is increasingly used for interior components. Its lightweight nature contributes to fuel efficiency, making it a smart choice. A study indicated that replacing heavier materials with birch plywood in vehicles could reduce weight by up to 15%. This reduction is critical as manufacturers strive to meet stringent fuel economy standards.

The construction industry also benefits from birch plywood. It is used for floorings, walls, and cabinetry. However, some projects face issues with moisture resistance. While birch plywood performs well in dry conditions, environments with high humidity can lead to warping. Industry experts recommend proper sealing techniques to mitigate these challenges. Overall, birch plywood continues to play a vital role in diverse applications, but being aware of its limitations is essential for optimal use.

Birch plywood has gained popularity due to its unique characteristics and versatility. A major factor is its strength. Birch trees grow in cold climates, producing dense wood that is strong yet lightweight. This makes birch plywood perfect for various applications, from furniture to cabinetry. Its smooth surface also offers an appealing finish, making it great for visible projects.

The aesthetic quality of birch plywood contributes to its appeal. It has a light, natural color that can brighten any space. This wood often features attractive grain patterns, adding a touch of elegance. Many designers and homeowners prefer birch for its modern look. It can be easily stained or painted, allowing for customization.

Tip: When choosing birch plywood, check the grades. Higher grades have fewer knots and imperfections. This will ensure a more seamless look for your project.

Another reason birch plywood is widely used is its sustainability. Birch trees grow relatively quickly compared to other hardwoods. This makes birch plywood an eco-friendly choice for those who are conscious of their environmental impact. Moreover, the manufacturing process has improved, minimizing waste.

Tip: Always look for certifications. This ensures the plywood is sourced responsibly. It promotes ethical practices in wood production.

Signup our newsletter to get update information, promotion or insight.