Choosing the right plywood sheets for your projects can be challenging. Industry expert John Anderson states, "Understanding the qualities of different plywood sheets can make all the difference." His insight emphasizes the importance of selecting the right material for structural integrity and aesthetics.

When selecting plywood sheets, consider factors like thickness, grade, and type. Different projects require different specifications. For example, furniture may need smoother surfaces, while construction may prioritize strength. Don't underestimate these details; they impact durability and overall appearance.

It's easy to overlook your project's specific needs, leading to potential issues down the line. Reflect on how your choices affect the final result. The right plywood sheets can elevate your project, while the wrong selection may hinder it. Always research and consult experts before making a decision.

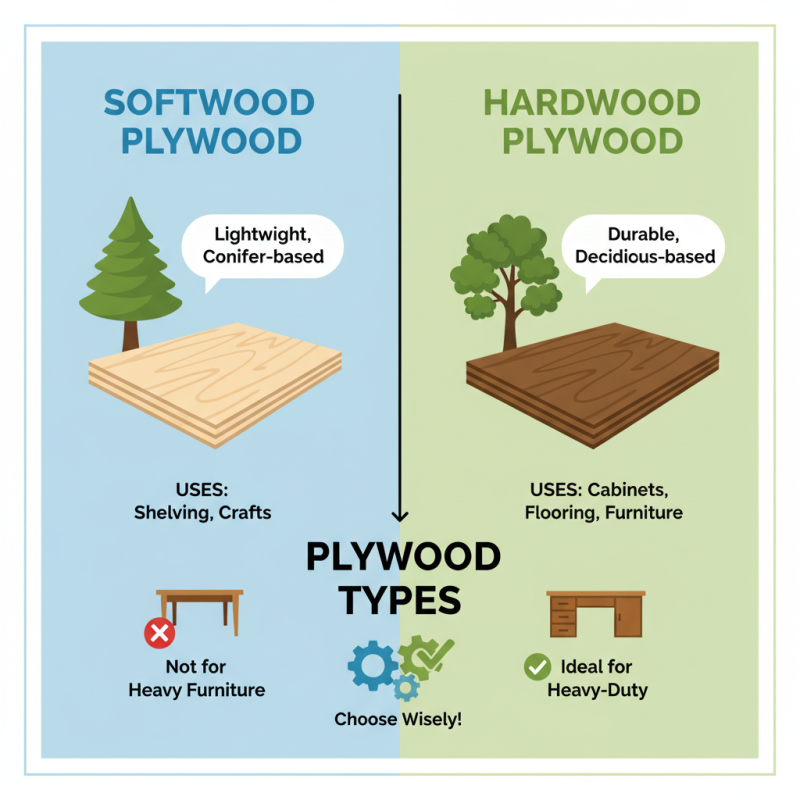

When it comes to selecting plywood sheets, understanding the different types available is essential. Plywood is mainly classified into softwood and hardwood categories. Softwood plywood, made from conifers, is lightweight. It's suitable for projects like shelving and crafts. However, it may not be the best choice for heavy-duty furniture, as it lacks durability.

On the other hand, hardwood plywood is denser and more robust. It comes from deciduous trees and offers better resistance to wear and tear. Ideal for cabinetry and fine furniture, it has a lovely finish. Yet, it can be more expensive. The grain patterns vary significantly, adding character and texture. Still, one must consider the cost when choosing thicker sheets for larger projects.

Another factor to consider is the plywood grade. Grades vary from A to D, with A being the highest quality. Lower-grade sheets may have defects. These could affect your finished project. It’s crucial to evaluate aesthetic and functional requirements when making your choice. Sometimes, compromising on one aspect might lead to an unsatisfactory result. You'll need to reflect on what matters most: looks or durability.

Evaluating plywood grades is crucial for any project. Plywood varies widely in quality. The grade determines strength, appearance, and durability. Higher grades like A or B have fewer defects. They are smoother and more reliable. Lower grades show more knots and blemishes. This can impact the final look of your project.

When selecting plywood, consider its intended use. For cabinets or furniture, higher quality is essential. You want a finish that looks good. For structural applications, strength matters more than appearance. Sometimes, lower grade plywood can suffice. It may save costs and work well in hidden areas.

Be mindful of sourcing plywood from different suppliers. Each may have varying interpretations of grades. Inspect the sheets personally when possible. Check for warping or swelling. These can affect your project’s outcome. Reflection on these aspects can lead to more informed choices.

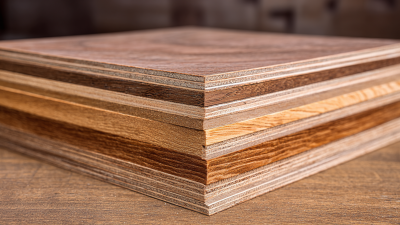

When selecting plywood sheets for your projects, key specifications like thickness and sheet size play pivotal roles in determining durability. Typically, plywood sheets come in various thicknesses, ranging from 1/8 inch to 1 inch or more. Thicker sheets generally offer enhanced strength, resisting warping and damage. For example, a report from the American Plywood Association suggests that a 3/4 inch plywood sheet withstands loads better than its thinner counterparts.

Sheet size is another critical factor. Standard sizes, such as 4x8 feet, are widely available. However, larger sheets can reduce the number of seams in your project, leading to enhanced structural integrity. An industry study indicates that projects utilizing fewer seams experience fewer points of failure. This can be especially important in high-stress applications.

When evaluating plywood, consider these tips: choose the right grade based on your project's needs. Higher grades tend to have fewer defects but may cost more. Also, ensure that the plywood adheres to relevant standards like CARB or EPA for safety. Remember, the right selection can prevent issues later on, such as bowing or cracking. Always reflect on your project requirements to make an informed choice.

When selecting plywood sheets, understanding adhesive types is crucial. Different bonding methods influence performance and durability. Plywood can be bonded using various adhesives, each with unique characteristics. For instance, polyurethane adhesives offer excellent moisture resistance. They are ideal for outdoor projects but can be messy to apply.

The most common adhesive types include PVA (polyvinyl acetate) and epoxy. A report from the Adhesive and Sealant Council states that PVAs are favored for interior applications. They provide strong bonds and are easy to clean up. However, they might not withstand extreme conditions as well as other adhesives. Performance metrics indicate that epoxy bonds can withstand higher tensile strength, making them suitable for structural applications.

In practice, choosing the right adhesive means weighing the environment and the stress the project will face. Sometimes, the best choice isn't the most expensive one. It's important to test the adhesives to see how they perform in real-life scenarios. Not all adhesives are created equal, and misjudgment can lead to project failures. This requires reflection on your specific needs and potential risks.

When selecting plywood sheets, sustainability is a key factor. Eco-friendly plywood is often certified by various standards. Look for labels like FSC or PEFC. These indicate responsible sourcing. Plywood from sustainably managed forests is less harmful to the environment. It ensures trees are replenished and habitats are preserved. Using certified plywood makes a positive impact.

However, not all products meet high sustainability standards. Some may carry misleading labels. Always research the sourcing details. Ask about the chain of custody. This step is crucial for ensuring that each sheet supports eco-friendly practices.

Consider the environmental impact of your choice. High-quality, sustainable plywood may cost more upfront. Yet, it lasts longer and reduces waste. Cutting corners for cheaper options can lead to regret. Reflect on your project’s environmental footprint. A responsible choice today can lead to a better tomorrow.

Signup our newsletter to get update information, promotion or insight.