The growing popularity of prefinished plywood in the construction and woodworking industries reflects a significant shift towards more efficient and high-quality materials. According to a report by Smithers Pira, the global market for engineered wood products, including prefinished plywood, is projected to reach $113 billion by 2025, driven by demand from residential and commercial construction sectors. This trend underscores the importance of selecting the right prefinished plywood for any project, as it not only influences the aesthetics and durability of the final product but also impacts overall construction timelines and costs.

When choosing prefinished plywood, factors such as wood species, core material, and surface finish play a critical role in achieving the desired performance and appearance. Recent data from the Forest Economic Advisors indicates that the consumption of plywood in North America has risen by 4% annually, highlighting a growing recognition of the benefits that prefinished options provide, such as reduced labor time and enhanced resistance to wear and tear. This emphasis on quality and efficiency propels the need for a comprehensive understanding of how to select the best prefinished plywood tailored to the specific requirements of any project, thereby maximizing value and satisfaction.

Prefinished plywood is a versatile building material that simplifies construction projects while enhancing aesthetic appeal. Defined as plywood that has been treated with finishes such as varnish or stain before reaching the job site, it offers several key benefits. One of the primary advantages is the time saved on finishing work; according to the American Plywood Association, prefinished options can cut labor costs by up to 30%. This efficiency is essential for both large-scale commercial projects and small home renovations alike.

In addition to saving time and labor, prefinished plywood provides a superior finish quality that can withstand wear over time. The protective layers applied during manufacturing help mitigate surface defects and enhance durability against moisture and scratches. A study from the Forest Products Laboratory emphasizes that properly treated plywood can extend the lifespan of projects by significantly resisting deterioration, thus making it an excellent choice for high-traffic areas. Furthermore, opting for prefinished variants can contribute to a project's overall sustainability, as many products are sourced from responsibly managed forests, aligning with the growing need for eco-friendly building materials in the industry.

| Tip No. | Tip | Benefit | Consideration |

|---|---|---|---|

| 1 | Choose the Right Grade | Ensures quality and durability | Understand different plywood grades |

| 2 | Assess Finish Type | Affects aesthetics and performance | Select between matte and gloss |

| 3 | Check for Environmental Standards | Promotes health and sustainability | Look for certifications like CARB |

| 4 | Evaluate Thickness | Determines strength and use-case | Choose based on project needs |

| 5 | Consider Edge Banding | Provides a finished look and durability | Check if edges are sealed |

| 6 | Inspect for Warping | Ensures structural integrity | Look for flat panels during selection |

| 7 | Review Cost | Budgeting for your project | Balance quality and price |

| 8 | Select Appropriate Size | Minimizes waste and maximizes usability | Know your project dimensions |

| 9 | Research Supplier Reputation | Ensures reliable quality | Look for reviews and testimonials |

| 10 | Plan for Installation | Ensures proper fit and function | Consider your skills and tools |

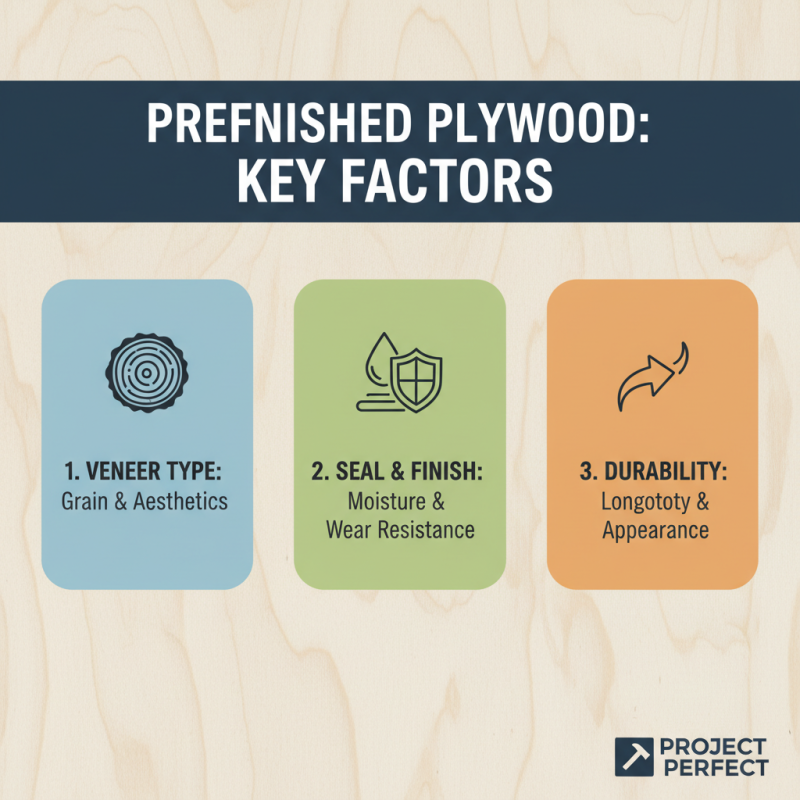

When selecting prefinished plywood for your next project, it’s essential to consider several key factors that can significantly impact both the appearance and functionality of your final result. Firstly, the type of veneer used is crucial, as it determines the aesthetic quality and durability of the plywood. Different species come with distinct grain patterns and colors, which can enhance the overall design of your project. Additionally, look for a plywood that has been properly sealed and finished, ensuring it is resistant to moisture and wear, which will prolong its lifespan and maintain its look.

Another vital consideration is the thickness of the plywood. Thicker sheets provide more strength and stability, making them suitable for structural applications. Conversely, thinner sheets can be lighter and easier to handle, which might be preferred for projects where weight is a concern. Pay attention to the core material as well, as plywood with a solid core will offer better strength and sound attenuation compared to those with hollow cores. Ultimately, evaluating these factors in tandem with your project requirements will guide you towards the best choice for prefinished plywood.

When selecting prefinished plywood for your next project, understanding the common grades and finishes is essential for ensuring durability and aesthetic appeal. The American Plywood Association (APA) categorizes plywood into various grades: A, B, C, and D, with A being the highest quality. Grade A plywood features a smooth, sanded surface ideal for visible areas, while Grade B has minor imperfections that can be filled. According to industry reports, the differences in grading can significantly affect the plywood's strength and suitability for specific applications, such as cabinetry or furniture-making, which often require a higher quality finish.

In terms of finishes, prefinished plywood typically comes in options like lacquer, veneer, or laminate. Each finish has its unique properties; for instance, a high-gloss lacquer can enhance the wood's natural beauty while providing a moisture-resistant surface. A study by the Wood Research Institute indicates that plywood with a varnished finish tends to have a longer lifespan due to its enhanced resistance to wear and tear. Moreover, the market trend shows an increasing preference for eco-friendly finishes, with recent surveys revealing that nearly 60% of consumers prioritize sustainability when choosing plywood. Understanding these grades and finishes will equip you with the knowledge necessary to make informed decisions for your projects.

When selecting prefinished plywood for your next project, it is essential to consider both the durability and sustainability of the material. Durability is a crucial factor, as it determines the longevity and performance of the plywood in various applications. Look for options that have a robust surface finish, which can enhance resistance to scratches, moisture, and wear. Additionally, consider the thickness and core composition of the plywood. Higher quality materials generally stand up better to heavy use and environmental stresses, ensuring that your investment lasts for years.

Sustainability is another critical aspect to evaluate. Opt for prefinished plywood sourced from responsibly managed forests to minimize environmental impact. Certifications such as the Forest Stewardship Council (FSC) can be an indication of sustainable practices in the sourcing process. Additionally, consider the adhesives and finishes used in the plywood; low-VOC (volatile organic compound) options contribute to better indoor air quality and a reduced ecological footprint. By prioritizing both durability and sustainability, you can make a well-informed decision that benefits your project and the planet.

When budgeting for your prefinished plywood project, the first step is to determine how much material you will need. Measuring the area where the plywood will be placed is crucial; this will help you calculate the total square footage required. It's advisable to factor in some extra material for mistakes or adjustments, typically an additional 10-15%. Once you have a clear idea of the quantity needed, you can begin researching the cost per sheet of prefinished plywood in your local area, which can vary significantly based on the type of wood, finish, and thickness.

In addition to material costs, don't neglect to consider other expenses associated with the project. This might include tools for installation, additional finishes if needed, and labor if you're not going the DIY route. Labor costs can quickly add up, so it's essential to get quotes from professionals if you plan on hiring help. Remember, a well-planned budget not only includes the purchase of materials but also accounts for potential overruns and unforeseen expenses to ensure that your project runs smoothly and stays within financial limits.

Signup our newsletter to get update information, promotion or insight.